[Introduction] China's automotive motors have obvious comparative advantages under global resource conditions and have great development potential. From the perspective of the new energy vehicle industry chain, the beneficiary side will mainly focus on the core components. The current status of domestic automotive drive motor industry: small industry in the motor industry, but the manufacturing threshold is high, there are still many gaps and shortcomings in the motor drive system, but domestic policy support will accelerate the pace of the industry.

China's automotive motors have obvious comparative advantages under global resource conditions and have great development potential. From the perspective of the new energy vehicle industry chain, the beneficiary side will mainly focus on the core components. The current status of domestic automotive drive motor industry: small industry in the motor industry, but the manufacturing threshold is high, there are still many gaps and shortcomings in the motor drive system, but domestic policy support will accelerate the pace of the industry.

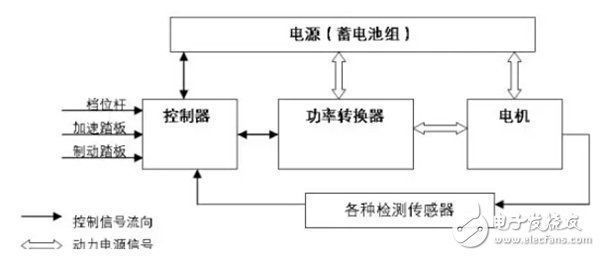

As one of the core components of new energy vehicles (battery, motor, electronic control), Figure 1, the drive motor and its control system have a promising future.

Introduction to the drive motor system

New energy vehicles have three major advantages: environmental protection, economy and simplicity. This is especially true in pure electric vehicles: the replacement of the fuel machine with an electric motor is driven by a motor without the need for an automatic transmission. Compared with the automatic transmission, the motor has a simple structure, mature technology and reliable operation.

The speed at which a conventional internal combustion engine can efficiently generate torque is limited to a narrow range, which is why a conventional internal combustion engine vehicle requires a large and complicated shifting mechanism; and the electric motor can efficiently generate torque over a relatively wide speed range. There is no need to shift gears during the running of pure electric vehicles, which is easy to operate and low in noise.

Compared with hybrid vehicles, pure electric vehicles use a single electric energy source. The electronic control system greatly reduces the internal mechanical transmission system of the automobile, and the structure is simplified, and the energy loss and noise caused by friction of mechanical parts are also reduced, thereby saving the interior space of the automobile. weight. The motor drive control system is the main execution structure in the operation of new energy vehicles. The drive motor and its control system are one of the core components (battery, motor, electric control) of new energy vehicles. The driving characteristics determine the main performance of the car. Indicator, which is an important part of electric vehicles.

The fuel cell vehicle FCV, the hybrid vehicle HEV and the pure electric vehicle EV in electric vehicles all use electric motors to drive the wheels. Choosing the right motor is an important factor to improve the cost performance of various types of electric vehicles. Therefore, research and development can improve At the same time, it is extremely important to meet the performance requirements of the vehicle during driving, and to have a motor drive that is durable, low in cost, and high in performance.

The drive motor system is one of the three core components of the new energy vehicle. The motor drive control system is the main execution structure of the new energy vehicle. Its driving characteristics determine the main performance indicators of the car. It is an important part of the electric car. The entire drive system of an electric vehicle includes two parts, a motor drive system and its mechanical transmission mechanism. The motor drive system is mainly composed of a motor, a power converter, a controller, various detection sensors, and a power supply, and the structure is as shown in FIG. 2 .

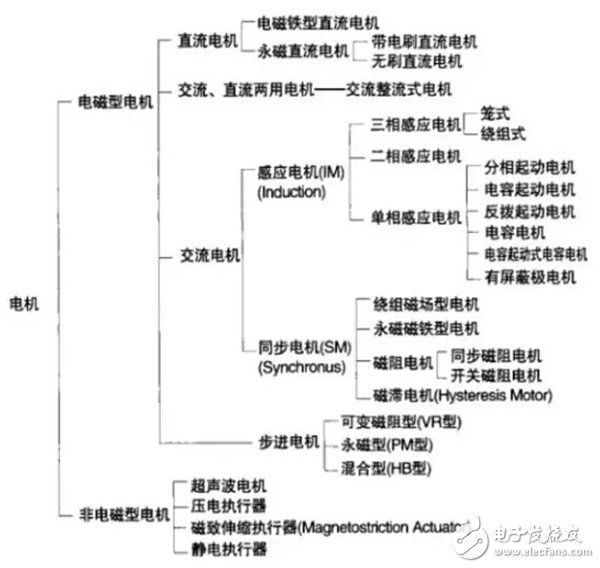

Motors generally require two functions: electric and power generation. Types of motors such as DC, AC, permanent magnet brushless or switched reluctance can be selected according to the type, as shown in Figure 3. The power converter is in the form of a DC/DC power converter, a DC/AC power converter, etc. according to the selected motor type. Its function is to convert the DC power of the battery to DC and AC of the corresponding voltage level according to the selected motor drive current requirement. Or pulse power supply.

The motor is a rotating electromagnetic machine that operates on the principle of electromagnetic induction and is used to convert electrical energy into mechanical energy. The electrical power is absorbed from the electrical system during operation and the mechanical power is output to the mechanical system. The motor drive system is mainly composed of a motor and a controller (inverter). The ratio of the cost of the drive motor and the motor controller is about 1:1. According to the design principle and the classification method, the specific structure and cost of the motor are composed. There are also differences. The control system of the motor mainly adjusts the running state of the motor to meet the requirements of different operating requirements of the whole vehicle. The principle and method of the control system are quite different for different types of motors.

Figure 2 Basic block diagram of the motor drive system

Figure 3 classification of the motor (according to the principle)

Basic requirements for electric motors for drive motors

Compare the application, advantages and disadvantages of four common motor drive systems.

1. The basic requirements for electric motor motors are as follows:

(1) The motor has a compact structure, small size, and limited package size, and must be specially designed according to the specific product.

(2) Light weight to reduce the overall weight of the vehicle. Aluminum alloy casing should be used as much as possible, and the rotation speed should be high to reduce the quality of the whole vehicle, increase the adaptability of the motor and the vehicle body, and expand the space available for the vehicle body, thereby improving the comfort of the ride.

(3) High reliability and controllable failure mode to ensure the safety of passengers.

(4) Provide accurate torque control with good dynamic performance.

(5) High efficiency and high power density. To ensure high efficiency over a wide range of speeds and torques, to reduce power loss and increase the driving range of a single charge.

(6) Low cost to reduce the overall cost of vehicle production.

(7) Wide speed range. It should include constant torque zone and constant power zone. The constant torque output of low speed operation is large to meet the requirements of fast start, acceleration and load climbing of the car; high speed operation outputs constant power and has a large speed range to meet High-speed driving requirements such as flat roads and overtaking.

(8) The instantaneous power is large and the overload capability is strong. It is necessary to ensure that the car has 4 to 5 times overload capacity to meet the requirements of short-term acceleration and maximum climbing.

(9) Good environmental adaptability. To adapt to the different regional environments in which the car itself travels, it can work normally even in harsh environments, with good high temperature and moisture resistance.

(10) Brake regeneration efficiency is high. When the car is decelerating, feedback braking can be achieved, energy is recovered and fed back to the battery, so that the electric car has the best energy utilization.

(11) Others. The utility model has the advantages of simple structure, low price, suitable for mass production, low noise during operation and convenient use and maintenance.

(12) Unlike general industrial motors, the drive motor used in automobiles should have the characteristics of wide speed regulation range, large starting torque, high backup power and high efficiency. In addition, it requires high reliability, high temperature resistance and moisture resistance. The structure is simple, the cost is low, the maintenance is simple, and it is suitable for mass production. In the future, China's electric motor drive motor system will develop toward permanent magnetization, digitization and integration.

2. Application of asynchronous motor (induction motor) in new energy vehicles

(1) Introduction to asynchronous motor

The induction motor is also called "asynchronous motor", that is, the rotor is placed in a rotating magnetic field, and under the action of the rotating magnetic field, a rotational moment is obtained, and thus the rotor rotates. The rotor is a rotatable conductor, usually in the form of a squirrel cage. The stator is the part of the motor that does not rotate. The main task is to generate a rotating magnetic field. The rotating magnetic field is not achieved mechanically. Instead, it is connected to a pair of electromagnets by alternating current, so that its magnetic pole properties change cyclically, so it is equivalent to a rotating magnetic field. Such a motor does not have a brush or a collector ring like a DC motor, and has a single-phase motor and a three-phase motor depending on the type of alternating current used.

(2) Characteristics of asynchronous motor

The asynchronous motor has the following advantages: compact structure, sturdy and durable; reliable operation and convenient maintenance; low price, small size, light weight; good environmental adaptability; low torque ripple and low noise. The AC asynchronous motor has low cost and high reliability, and the inverter does not generate a back electromotive force even if it is short-circuited due to damage, so there is no possibility of sudden braking.

Therefore, it is widely used in large-scale high-speed electric vehicles. Three-phase cage asynchronous motors have a wide range of power capacities ranging from a few watts to a few kilowatts. It can be air-cooled or liquid-cooled, with high degree of freedom in cooling, good environmental adaptability, and regenerative braking. Compared with DC motors of the same power, the efficiency is higher and the weight is about half lighter.

At the same time, it has the following disadvantages: low power factor, it must absorb reactive current from the power grid to establish magnetic field during operation; control is complex, susceptible to motor parameters and load changes; rotor is not easy to dissipate; poor speed regulation performance, narrow speed range .

Advantage analysis: The electric motor for new energy vehicles generates action by obtaining limited energy from the battery, so it is required to be efficient in various environments. Therefore, performance requirements are more stringent than those of general industrial motors. Suitable for electric vehicles, it is necessary to meet several characteristics: small size and light weight (sturdy), high efficiency (long driving range after one charge), and wide range under low speed and large torque. Constant output characteristics, long life and high reliability, low noise and low cost. However, in reality, all motors that satisfy the above characteristics have not been developed. The motors currently more suitable for new energy vehicles are AC asynchronous motors and PM motors.

(3) Control system of asynchronous motor

Since the AC three-phase induction motor cannot directly use the DC power, the inverter device is required to perform the conversion control. When the new energy vehicle is decelerating or braking, the motor is in the state of generating braking, charging the battery to convert mechanical energy into electrical energy. In a new energy vehicle, a PWM power inverter composed of a power semiconductor device converts the DC power supplied from the battery power source into an AC power whose frequency and amplitude can be adjusted.

The control methods of the three-phase asynchronous motor inverter mainly include V/f constant control method, slip rate control method, vector control method and direct torque control method (DTC). Before the 1990s, the first two control modes were mainly used, but the torque control range was small, the torque characteristics were not ideal, and it was not suitable for electric vehicles that required frequent starting and acceleration and deceleration. Now, the latter two control methods are currently in the mainstream.

(4) Application status of asynchronous motor

In the United States, there are more applications for asynchronous motors, which are also artificially related to road conditions. In the United States, highways already have a certain scale. Except for large cities, cars generally continue to travel at a certain high speed, so asynchronous motors that can achieve high speed operation and high efficiency at high speed are widely used. In China, with the development of highway scale, the application of AC asynchronous motors in new energy vehicles will become more and more important.

3. Application of permanent magnet brushless motor in new energy vehicles

With the rapid development of power electronics technology, microelectronic technology, microcomputer technology, rare earth permanent magnet materials, sensor technology and motor control theory in recent years, AC drive technology has gradually matured.

Compared with the existing series excitation or shunt brushed DC motor drive system, the permanent magnet brushless motor has the advantages of high power density, small size, high efficiency, simple and firm structure, easy maintenance, and the use of permanent magnet brushless motor. The electric vehicle drive system of the drive component has low operating and maintenance costs; the fully digital and modular structure design makes the drive interface flexible, the control capability is stronger, and the operation is more comfortable; the application of energy feedback brake technology can reduce the wear of the brake pad At the same time, increase the driving range of the car.

Therefore, based on the development needs and technical status of the electric vehicle market, designing and developing a fully digital electric vehicle permanent magnet brushless motor drive system with reliable, low cost and excellent performance has important practical significance for the development of the electric vehicle industry.

(1) Introduction to permanent magnet synchronous motor

There are two ways to establish the air gap magnetic field necessary for electromechanical energy conversion in the motor. One is to generate a magnetic field by passing a current through the windings of the motor. This method requires special windings and corresponding devices, and requires constant supply of energy to maintain current flow, such as ordinary DC motors and synchronous motors. The other is to generate a magnetic field from a permanent magnet, which simplifies the motor structure and saves energy. A motor that generates a magnetic field from a permanent magnet is a permanent magnet motor.

It uses a permanent magnet to establish a synchronous magnetic field of the excitation magnetic field, the stator generates a rotating magnetic field, and the rotor is made of a permanent magnet material. In order to achieve energy conversion, a synchronous generator needs to have a DC magnetic field to generate a DC current of this magnetic field, which is called the excitation current of the generator. According to the excitation current supply mode, any generator that obtains the excitation current from other power sources is called a separately excited generator. If the excitation power is obtained from the generator itself, it is called a self-excited generator.

(2) Characteristics of permanent magnet synchronous motor

Permanent magnet synchronous motor has the following advantages: large power factor, high efficiency, high power density; simple structure, easy maintenance, long service life and high reliability; good speed regulation performance, high precision; good transient characteristics, moment of inertia Low, fast response; high frequency, high output torque, extreme speed and braking performance are superior to other types of motors; electronic power devices are used as reversing devices, which are flexible in driving and controllable; flexible in shape and size. It is convenient for shape design; the motor is small in size and light in weight after using rare earth permanent magnet material.

However, the permanent magnet synchronous motor also has the following disadvantages: the motor cost is high; in the constant power mode, the operation is more complicated, the control system cost is higher; the weak magnetic capability is poor, the speed regulation range is limited; the power range is small, and the magnetic material process is small. Influence and limitation, the maximum power is only tens of kilowatts; the rated current is large at low speed, the loss is large, and the efficiency is low; when the permanent magnet material is subjected to vibration, high temperature and overload current, the magnetic permeability may be degraded or demagnetized. The phenomenon will reduce the performance of the permanent magnet motor, and in severe cases, the motor will be damaged, and must be strictly controlled in use so that it does not overload. The magnetic field of the permanent magnet material is not variable. To increase the power of the motor, its volume will be large; the corrosion resistance is poor; it is not easy to assemble.

(3) Advantages of permanent magnet motor as drive motor

1 Torque, high power density and large starting torque. The air gap magnetic density of the permanent magnet motor can be greatly improved, and the motor index can achieve the optimal design, so that the motor volume is reduced and the weight is reduced. The volume, weight and materials used for the rare earth permanent magnet motor of the same capacity can be reduced by about 30%. The permanent magnet drive motor has a large starting torque and can provide an effective starting torque when the vehicle is started to meet the running requirements of the vehicle.

2 The force index is good. When the Y series motor is operated under 60% load, the efficiency is reduced by 15%, the power factor is reduced by 30%, and the force index is reduced by 40%. The efficiency and power factor of the permanent magnet motor drop slightly. When the motor has only 20% load, the force index is still more than 80% of the full load. At the same time, the permanent torque range of the permanent magnet brushless synchronous motor is relatively long, extending to about 50% of the maximum speed of the motor, which is very helpful for improving the low speed dynamic performance of the automobile.

3 efficient and energy saving. After the rare earth permanent magnet material is embedded on the rotor, the rotor and the stator magnetic field run synchronously during normal operation, and the rotor winding has no induced current, and there is no rotor resistance and hysteresis loss, which improves the efficiency of the motor. The permanent magnet motor not only reduces the resistance loss, but also effectively increases the power factor. Permanent magnet synchronous motors maintain high efficiency and power factor, such as in the range of 25% to 120% of rated load.

4 simple structure and high reliability. Excitation with permanent magnet material can replace the excitation coil of the original excitation motor with one or more permanent magnets, the parts are greatly reduced, the structure is greatly simplified, the processability of the motor is improved, and the mechanical reliability of the motor operation is greatly Enhanced and increased life. There is no resistance loss in the rotor winding, there is almost no reactive current in the stator winding, and the motor temperature rise is low, which can also reduce the load of the vehicle cooling system and further improve the efficiency of the whole vehicle operation.

(4) Permanent magnet synchronous motor control system

The control technology of permanent magnet motor is similar to that of induction motor. The control strategy is mainly focused on improving low speed torque characteristics and high speed constant power characteristics. At present, permanent magnet synchronous motors often use vector control at low speeds, including air gap field orientation, rotor flux linkage orientation, stator flux linkage orientation, etc., while at high speeds, permanent magnet synchronous motors typically use field weakening control.

(5) Current status of permanent magnet motor applications

The design theory, calculation method, detection technology and manufacturing process of rare earth permanent magnet motor are constantly improving and developing, and the performance and reliability of permanent magnet materials are constantly improving. The rapid development of power electronics technology, large-scale integrated circuits and computer technology has also played a positive role in the development of permanent magnet drive motors. With the rapid development of hybrid and pure electric vehicles in the future, permanent magnet drive motors will usher in a period of more rapid development, and their development trend will also show the following characteristics: high power density, high torque density, high controllable Sex, high efficiency, high performance, high price ratio, etc., to meet the actual needs of hybrid vehicles and pure electric vehicles.

4. Application of switched reluctance motor in new energy vehicles

(1) Introduction to switched reluctance motor

Switched Reluctance Drive (SRD) is the latest generation of stepless speed regulation system developed after the variable frequency speed control system and brushless DC motor speed control system. It is a collection of modern microelectronic technology, digital technology, power electronics technology, infrared. Optoelectronic technology and modern electromagnetic theory, design and production technology as one of the integration of light, machine and electricity. It has the advantages of a speed control system with both DC and AC speed control systems.

Switched reluctance motors cover a variety of high and low speed drive speed control systems with power ranges from 10W to 5MW. There are many potential fields for switching reluctance motors, which can be widely used in various places where speed regulation and high efficiency are required (electric vehicle drive, general industry, household appliances, textile machinery, electric drive systems, etc.).

The working principle of the switched reluctance motor: The operation of the switched reluctance motor follows the "minimum reluctance principle" - the flux always closes along the path with the smallest reluctance. When the core with a certain shape moves to the minimum reluctance position, its main axis must coincide with the axis of the magnetic field.

(2) Switched reluctance motor features

Its structure is simpler than any other kind of motor. There are no slip rings, windings and permanent magnets on the rotor of the motor, but there are simple concentrated windings on the stator. The ends of the windings are short and there is no phase jumper. Maintenance and repair is easy. Therefore, the reliability is good and the rotational speed can reach 15000r/min. The efficiency can reach 85%~93%, which is higher than AC induction motor. The loss is mainly in the stator, the motor is easy to cool; the rotor element permanent magnet is easy to achieve various special requirements of torque-speed characteristics, and maintains high efficiency over a wide range. More suitable for electric vehicle dynamic performance requirements.

Switched reluctance motors also have the advantages of efficient operation over a wide range of speeds and torques, flexible control, four-image operation, fast response, and low cost. Good processability, suitable for high speed, strong environmental adaptability; the direction of motor torque is independent of the direction of winding current; suitable for frequent start and stop and forward and reverse conversion operation; small starting current, large torque; many controllable parameters, The speed regulation performance is good; the regenerative braking ability is strong; the materials of the stator and the rotor are all made of silicon steel sheets, which are easy to obtain and recycle.

However, the switched reluctance motor has large torque fluctuation, requires position detector, nonlinear characteristics of the system, the magnetic field is skipping rotation, the control system is complicated, and the DC power supply generates a large pulse current and the like. The position detector is a key component of the switched reluctance motor, and its performance has an important influence on the control operation of the switched reluctance motor. Since the switched reluctance motor is a double salient pole structure, torque ripple is inevitable, and noise is the main disadvantage of the switched reluctance motor.

However, recent studies have shown that the noise of a switched reluctance motor can be well suppressed by reasonable design, manufacturing and control techniques. In addition, since the output torque of the switched reluctance motor fluctuates greatly, the DC current fluctuation of the power converter is also large, so a large filter capacitor is required to be mounted on the DC bus.

(3) Control system of switched reluctance motor

The core of the switched reluctance motor drive system is the switched reluctance motor (SRM), which involves multi-disciplinary knowledge of electric motors, power electronics, microcomputers, control, photoelectric conversion, angle measurement, etc. The structure is complex and the control system requirements are unique. The control methods of induction motors and permanent magnet synchronous motors are often difficult to meet the control requirements of the system. There are currently fewer applications for electric vehicles. Its main research direction is model research.

Since the switched reluctance motor has obvious nonlinear characteristics, the system is difficult to model, and the general linear control method is not suitable for the switched reluctance motor system. At present, mainly use fuzzy logic control, neural network control and so on.

Its control system includes power converters, controllers and position sensors and speed detectors.

1 power converter

The excitation winding of the switched reluctance motor, regardless of the forward current or reverse current, has the same torque direction, and the commutation period requires only one power switch tube with a smaller capacity for each phase. The power converter circuit is simpler, not There will be a straight-through fault with good reliability, easy to implement soft start and four-quadrant operation of the system, and strong regenerative braking capability. The cost is lower than the inverter control system of the AC three-phase induction motor.

2 controller

The controller is composed of components such as a microprocessor and a digital logic circuit. The microprocessor analyzes and processes the position of the motor rotor fed back by the position detector and the current detector according to the command input by the driver, and makes a decision in an instant, and issues a series of execution commands to control the switched reluctance motor. Adapt to the operation of electric vehicles under different conditions. The performance of the controller and the flexibility of the adjustment depend on the performance of the microprocessor's software and hardware.

3 position detector

Switched reluctance motors require high-precision position detectors to provide control system with signals that change the position, speed, and current of the motor's rotor, and require higher switching frequencies to reduce the noise of the switched reluctance motor.

5. Application of DC motor in new energy vehicles

DC motors can be divided into permanent magnet DC motors and winding excitation motors. Generally, the former uses small power, and the latter uses high power. The latter mainly discusses the latter.

(1) Introduction to DC motor

DC motor: A rotating electrical machine that converts DC electrical energy into mechanical energy (DC motor) or converts mechanical energy into DC electrical energy (DC generator).

The structure of the DC motor should consist of two parts, the stator and the rotor. The part of the DC motor that is stationary during operation is called the stator. The main function of the stator is to generate a magnetic field. It consists of a base, a main pole, a commutating pole, an end cover, a bearing and a brush device. The part that rotates during operation is called the rotor. Its main function is to generate electromagnetic torque and induced electromotive force. It is the hub of DC motor for energy conversion, so it is usually called armature. It is changed by the shaft, armature core, armature winding, and It consists of a transmitter and a fan.

Brushed DC motors are widely used in applications requiring adjustable speed, good speed regulation, and frequent starting, braking, and reversing.

(2) Characteristics of DC motor

The DC motor has the following advantages: the structure is simple; it has excellent electromagnetic torque control characteristics, and can realize constant torque below base speed and constant power above base speed, which can meet the low torque, high torque and high torque of the vehicle. Requirements; frequent quick start, braking and reversing; smooth speed regulation, stepless, precise, convenient, wide range; strong anti-overload capability, able to withstand frequent impact loads; simple control method, only need voltage control, no Need to detect the magnetic pole position.

However, it also has the following disadvantages: it is equipped with a brush and a commutator, and the surface of the commutator is prone to sparking when running at high speed and large load. At the same time, the commutator is difficult to maintain, and it is difficult to develop to large capacity and high speed. It will generate electromagnetic interference; it should not be used in dusty, humid, flammable and explosive environment; high price, large volume and high quality. The electromagnetic interference generated by the electric spark will be fatal for highly electronic electric vehicles. With the development of electronic force technology and control theory, the application of DC motors in electric vehicles is at a disadvantage compared to other drive systems, and has been gradually eliminated.

(3) DC motor control system

The DC motor control system is mainly composed of a chopper and a central controller. According to the output torque of the DC motor, the input voltage and current of the motor are controlled by a chopper to control and drive the operation of the DC motor.

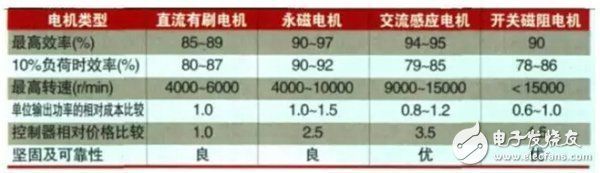

6, a comparison of various motors

Let us first compare the development history of various motors. From Figure 4 we can see that brushed DC motors, general synchronous motors, induction motors and brushed magnet motors have the longest commercialization history, and their products have been updated continuously, and so far In the application. Since the 1980s, commercial surface permanent magnet synchronous motors have been introduced, and switched reluctance motors, built-in permanent magnet synchronous motors and the latest synchronous reluctance motors developed since the 1990s have entered the market one after another, and in electric vehicles and Get the app on a hybrid car.

Figure 4: Comparison of development history of various motors

At the current level of development, the basic performance of various types of drive motors is compared as follows:

Figure 5: Comparison of basic performance of various types of drive motors

Figure 6: Comparison of basic performance of various types of drive motors

Then compare the various motors on which new energy vehicles are widely used. Asynchronous motors are mainly used in pure electric vehicles. Permanent magnet synchronous motors are mainly used in hybrid vehicles. Switched reluctance motors are mainly used in passenger cars. From the application of different types of new energy vehicle drive motors in China, AC asynchronous induction motors and switched reluctance motors are mainly used in new energy commercial vehicles, especially new energy buses, and the practical assembly applications of switched reluctance motors are less; Permanent magnet synchronous motors are mainly used in new energy passenger cars.

Finally, compare the development status of various motors in China:

(1) AC asynchronous motor drive system China has established a development platform with independent intellectual property asynchronous motor drive system, forming a development, manufacturing, testing and service system for small batch production; product performance basically meets the needs of the entire vehicle, high-power asynchronous The motor system has been widely used in various types of electric buses; the product reliability has been initially verified through demonstration operation and small-scale market application.

(2) The switched reluctance motor drive system has formed optimized design and independent research and development capabilities. Through reasonable design of motor structure and improved control technology, the product performance basically meets the needs of the whole vehicle; some companies have an annual production capacity of 2,000 sets, capable of To meet the needs of small batches of supporting equipment, some of the products have been equipped with demonstration vehicles for a long time, with good results.

(3) Brushless DC motor drive system Domestic enterprises have effectively improved the performance of brushless DC motor products by reasonably designing and improving control technology, and basically meet the needs of electric vehicles; they have initially possessed mechatronics design capabilities.

(4) Permanent magnet synchronous motor drive system has formed certain R&D and production capacity, and developed different series of products, which can be applied to all kinds of electric vehicles; some technical indicators of the products are close to the international advanced level, but the overall level is still certain with foreign countries. Gap; basically has the integrated design capability of permanent magnet synchronous motor; most companies are still in small-scale trial production, and a few companies have invested in the establishment of a dedicated production line for automotive drive motor systems.

(5) Permanent magnet motor materials The main materials of permanent magnet motors are NdFeB magnets and silicon steel. Some companies have mastered the overall magnetization technology of magnetizing the rotor magnets of the motor. The maximum working temperature of NdFeB permanent magnets developed in China can be 280 °C, but the technical level is still far from Germany and Japan. Silicon steel is an important magnetic material for manufacturing motor cores. Its cost accounts for about 20% of the motor body. Its thickness has a great influence on iron consumption. Japan has produced 0.27mm silicon steel sheets for automotive motors. China has only developed 0.35. Mm silicon steel sheet.

7. Future prospects of new energy vehicle drive motors

The current development direction of new energy vehicle drive motors has the following aspects: small size and light weight; high efficiency; better torque characteristics; long service life, high reliability; low noise; low price. With the passage of time, the development of new energy-driven motors presents the following trends:

1 Motor body permanent magnetization: permanent magnet motor has the advantages of high torque density, high power density, high efficiency and high reliability. China has the world's most abundant rare earth resources, so high-performance permanent magnet motor is an important development direction of China's vehicle drive motor.

2 Motor control digitization: The emergence of dedicated chips and digital signal processors has promoted the digitization of motor controllers, improved the control accuracy of motor systems, and effectively reduced the system size.

3 motor system integration: through the integration of electromechanical integration (motor and engine integration or motor and gearbox integration) and controller, it is beneficial to reduce the weight and volume of the drive system, which can effectively reduce the system manufacturing cost.

Let's talk about a variety of future motors. With the rapid development of new energy vehicle drive technology, many new structures or new concept motors have been put into research. Among them, the new permanent magnet brushless motor is one of the most promising motors, including hybrid excitation type, hub type, double stator type, memory type and magnetic gear composite type. In addition, amorphous motors have also entered the field of new energy vehicles. As a new generation of high-performance motors, their superiority will definitely play a huge role in promoting the development of the new energy automobile industry.

(1) Hybrid Excitation Motor

Hybrid excitation motor is to change the topological structure of the motor under the premise of maintaining high efficiency of the motor. The two main excitation sources jointly generate the main magnetic field of the motor to realize the adjustment and control of the main magnetic field of the motor, improve the motor speed regulation, drive performance or voltage regulation. A new class of motors with characteristics. It not only inherits many characteristics of permanent magnet motor, but also has the advantages of smooth and adjustable air gap magnetic field of electric excitation motor. Such as permanent magnet switched reluctance motors and permanent magnet synchronous reluctance motors.

(2) Double stator permanent magnet motor

The double stator motor is a new permanent magnet brushless motor that increases the number of stators based on the existing motor volume and changes the number of air gaps from one layer to two layers or multiple layers. Due to the superposition of the torque, the electromagnetic torque acting on the rotor is correspondingly increased, thereby increasing the overall torque density and power density of the motor. Because of the high mechanical integration of this motor, it has the characteristics of fast response, good dynamic characteristics, high utilization of structural materials and flexible drive.

(3) Memory motor

The memory motor is also called a flux-controlled permanent magnet motor. The difference from the general permanent magnet motor is that the degree of magnetization of the permanent magnet material itself can be changed by applying a magnetization or demagnetizing electromotive force in a short time, and charging The degree of magnetization after magnetic and demagnetization can also be preserved in memory. Therefore, it has a wider speed range and avoids additional excitation loss. It is essentially a new simple and efficient weak magnetic control technology.

(4) Magnetic gear permanent magnet brushless composite motor

The motor is a composite motor that integrates a brushless DC drive motor and a coaxial magnetic gear. The so-called coaxial magnetic gear is a high-performance, non-contact variable speed transmission device based on the principle of harmonic modulation. This kind of motor skillfully utilizes the hollow part of the inner rotor of the coaxial magnetic gear, inserts the stator of the motor into it, and directly rives the tire on the outer rotor of the gear, realizing the integration of the motor, the magnetic gear and the tire, effectively improving the Space utilization.

(5) Amorphous motor

Amorphous motor is a new type of motor that uses amorphous alloy to replace traditional silicon steel sheet as core material, which is efficient, energy-saving and pollution-free. Its low frequency loss at high frequencies has high efficiency; compared with ordinary motors of the same standard, the volume and mass are greatly reduced, which greatly improves the utilization of energy and resources.

For the same new energy vehicles, if you use an amorphous motor, you can increase the mileage by more than 30%, and in the case of the same mileage, the battery can save 30%. In short, amorphous motors will become the next generation of high-efficiency motors to replace traditional motors with their high efficiency and high power density.